Data Collection Form Structure

AIMPF researchers will have access to all the data being collected. This ensures that the data is not siloed and can be shared and utilized by the entire research community. Sharing the data promotes collaboration, enables cross-disciplinary research, and allows for the discovery of new insights and knowledge. It also helps to avoid duplication of efforts and encourages transparency in the research process. By making the data easily accessible, researchers can build upon each other’s work, validate findings, and contribute to the advancement of scientific knowledge. Additionally, open access to the data encourages reproducibility and facilitates the verification of research results.

Data collection forms are JSON schemas that users fill and submit to the database while they are performing a task. The task could be a pre-processing such as arc melting of alloys, a DED printing, or post-processing such as heat treatment using furnaces.

The data collection form is a way to standardize the data collection process and ensure that the data is collected in a consistent manner. This is important because the data collected will be used for analysis and decision-making in the later segment of the pipeline.

All data collection forms are designed through communication with the domain experts, and each piece of equipment will have at least one data collection form associated with it. Equipment with more complex functions may have multiple data collection forms associated with it, where different workflows are performed for different tasks.

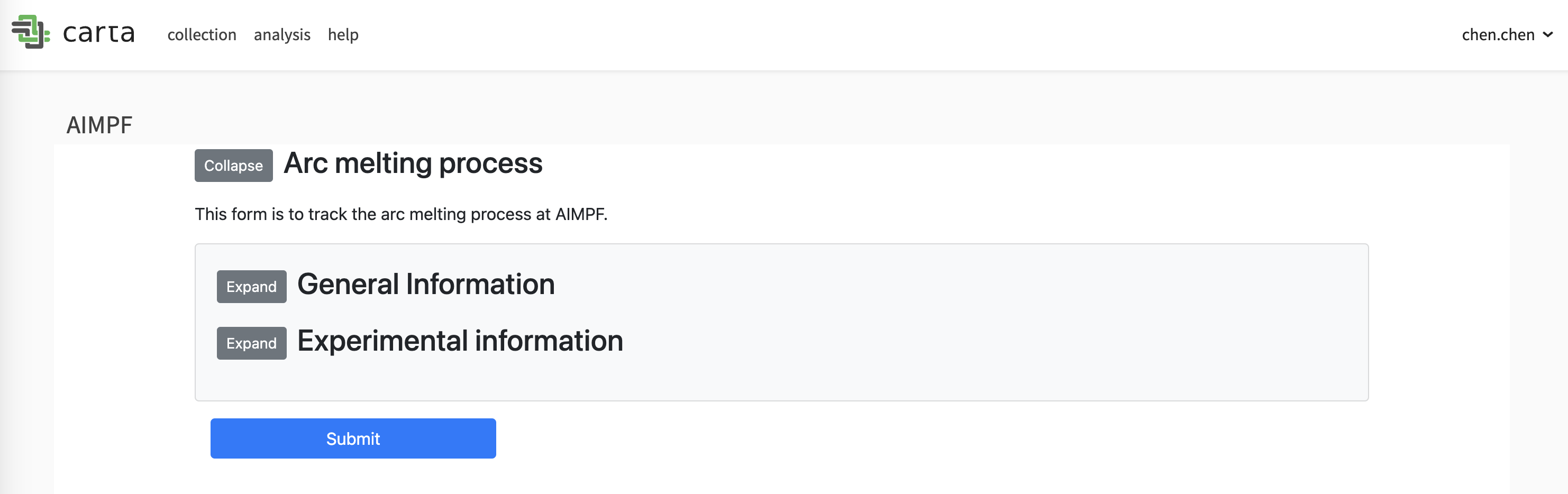

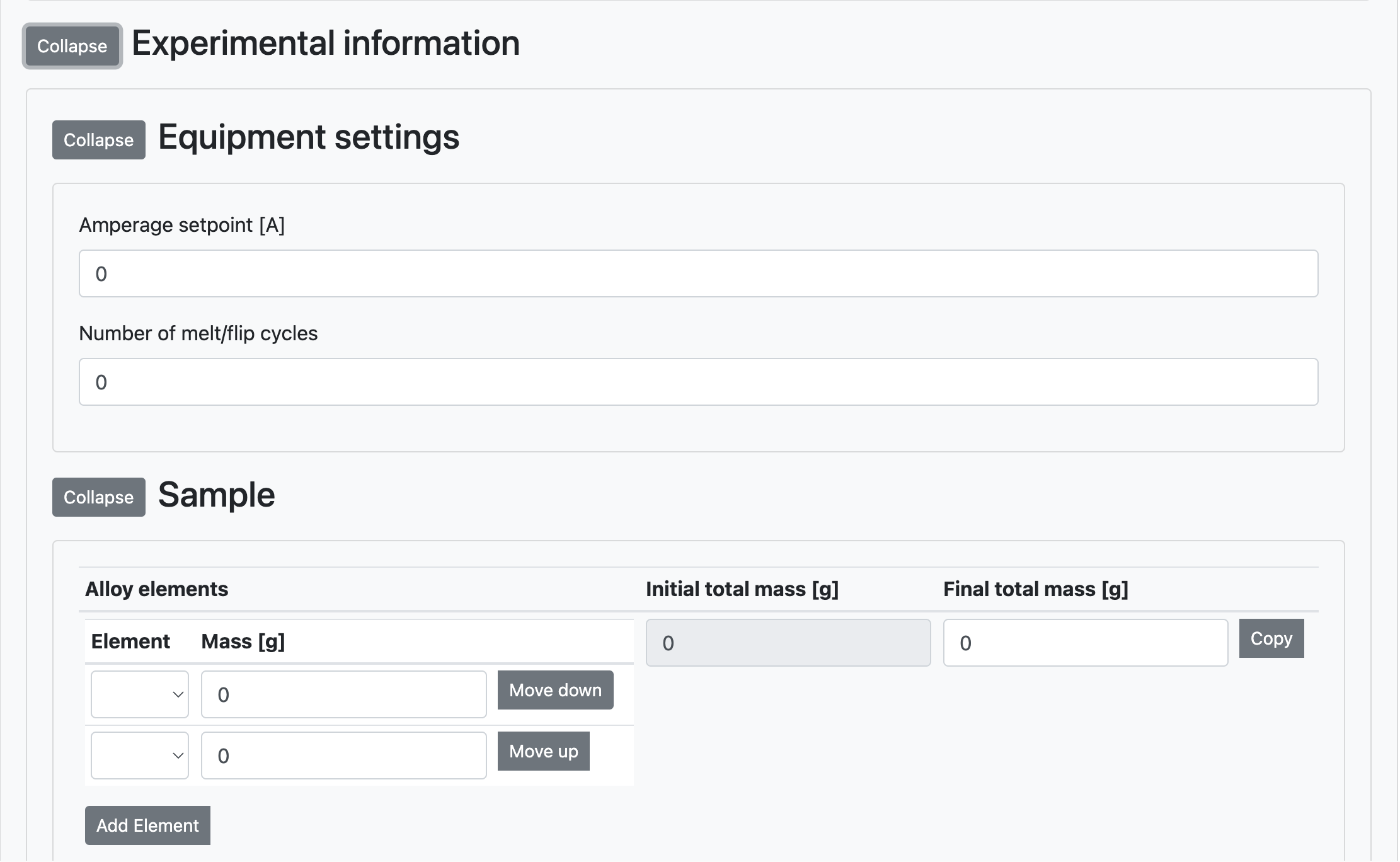

Example: Arc melting data collection form

Typically, a data collection form will have the following structure, and we will use the arc melting data collection form as an example to illustrate the structure:

Form Name: The name of the form, e.g., “Arc melting process”.

Form Description: A brief description of the form, e.g., “This form is to track the arc melting process at AIMPF”.

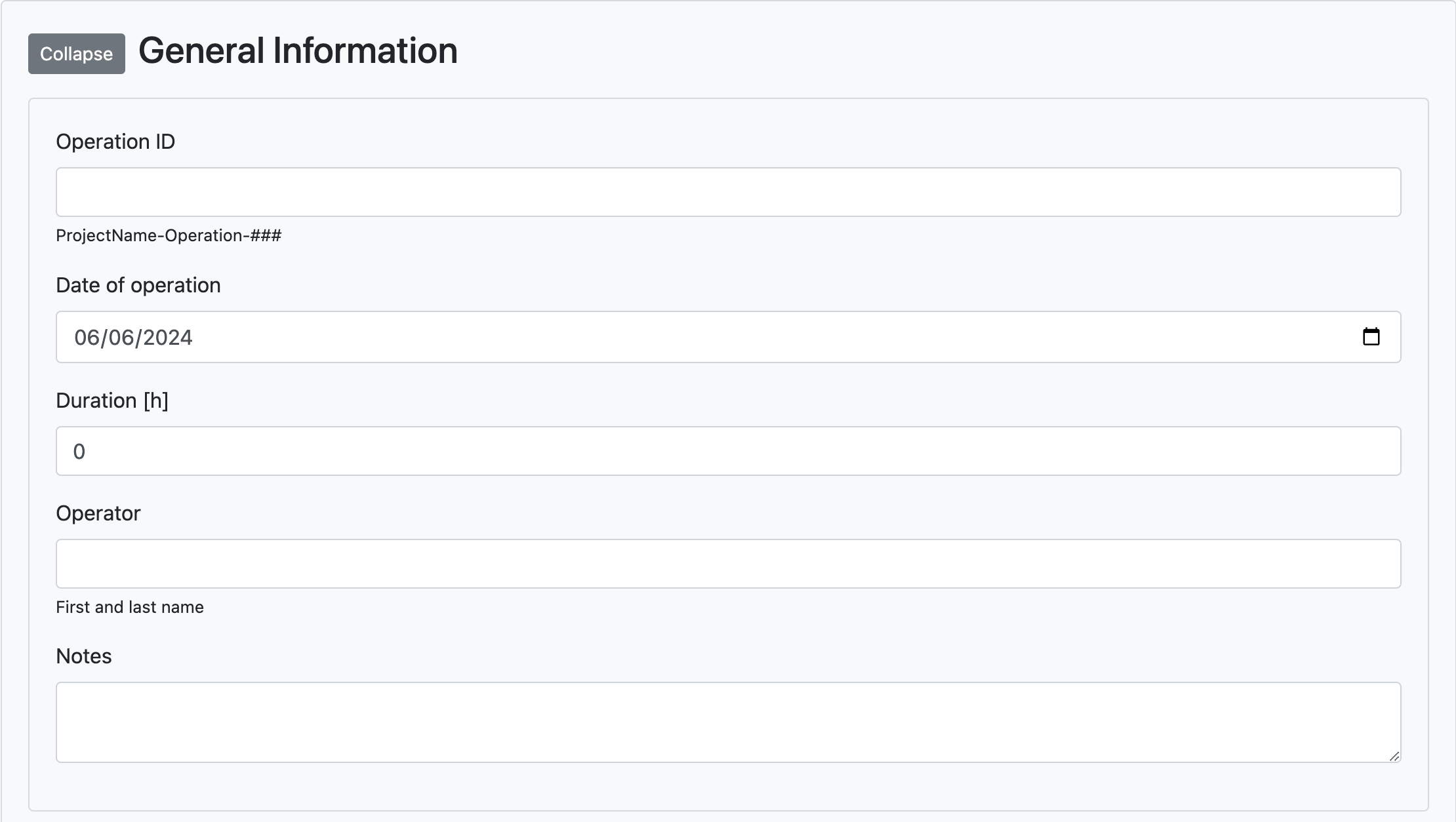

General Information section: General information about the form, such as the Operation ID, Date of Operation, Duration, Operator, and Notes. This section is common to all data collection forms. Some fields might have a default value which could save users’ time while filling it out. For example, the “Date of Operation” field could have the current date as the default value.

Experimental information section: Information specific to the experiment. This section could possibly include equipment settings and sample information. Therefore, this section will vary a lot depending on the type of experiment being performed, which is why it is important to have conversations with domain experts to understand the requirements.

Submit button: A button that users can click to submit the form to the database. Once submitted, users will be able to find it in the database and modifications can be made if there is a need.

The above structure is a general guideline, and the actual structure of the data collection form will depend on the specific requirements of the equipment and the experiment being performed.

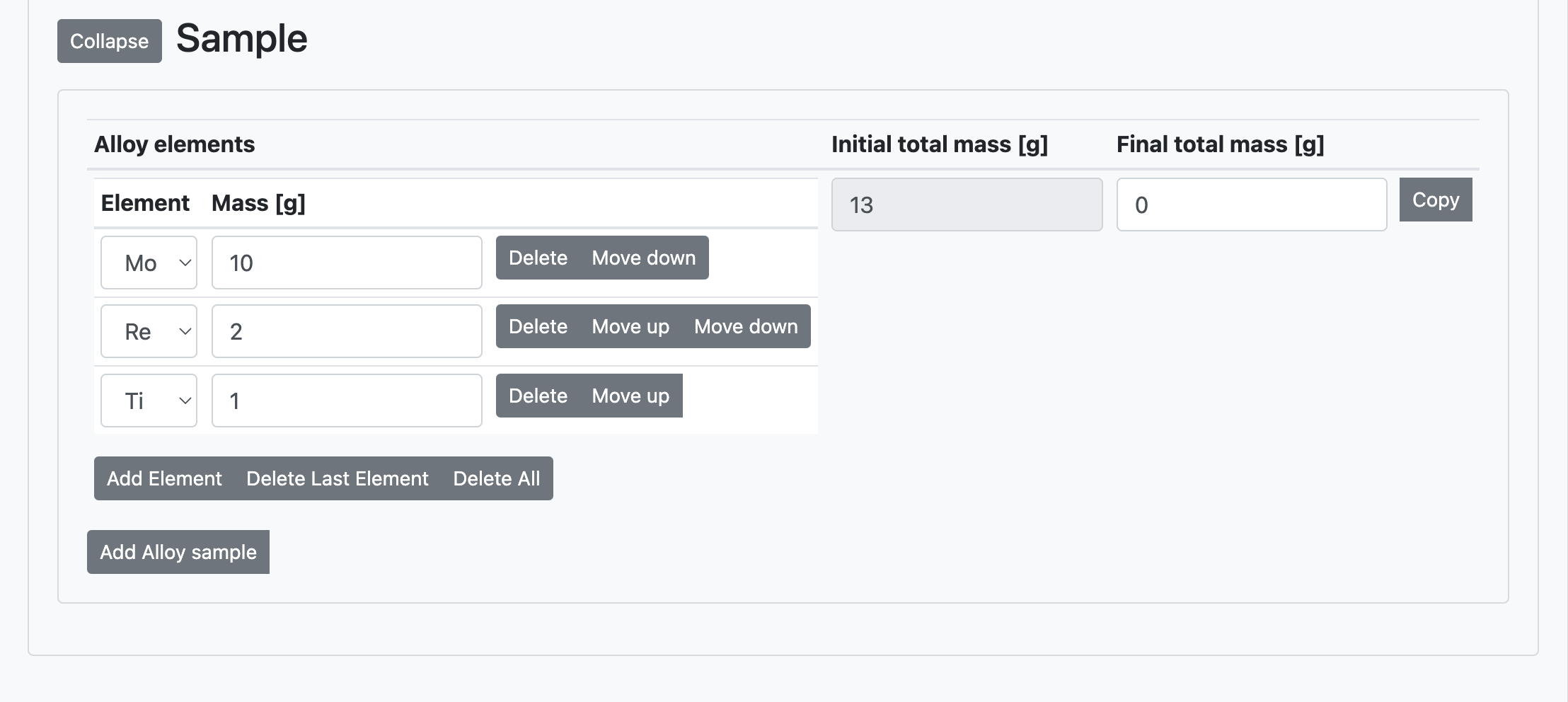

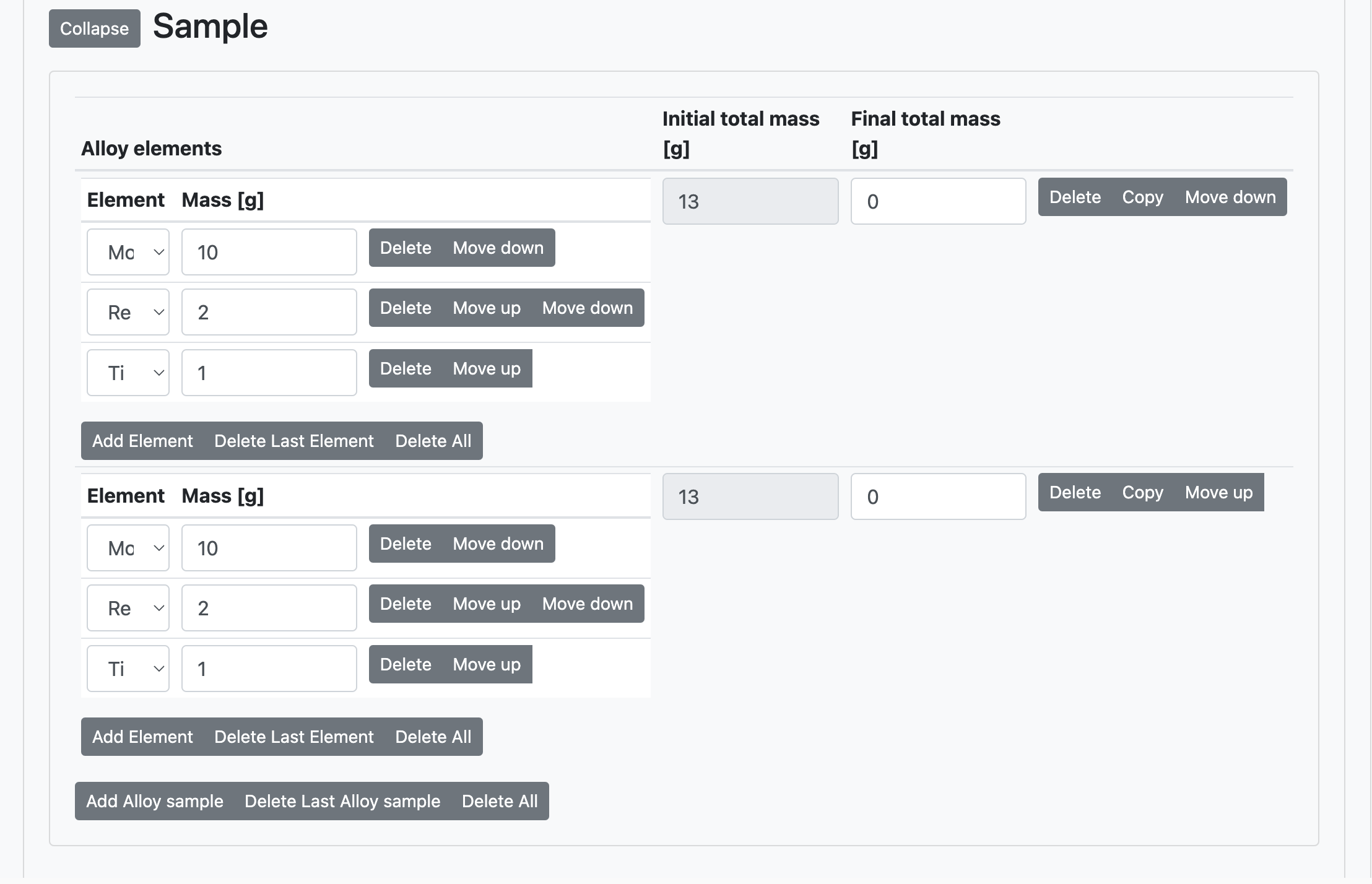

Note that, the data collection form is not simply a static form. There are some interactive elements in the form besides the submit button. For example, in the “Sample” subsection under the “Experimental Information” section, users can choose element from the drop-down list and specify the weight of the sample. The author can add additional elements to the alloy composition, and the “Initial total mass [g]” will be updated automatically by summing up the weights of all the elements in the alloy.

To record multiple samples in a single experiment run, users can click “Add Alloy sample” to add new samples. Or they can click “Copy” button on the right side of any sample to duplicate it and make modification based on that.

Other functions

Here we list other functions that can be realized in the data collection form:

Validation: The form can be validated to ensure that the data entered is in the correct format. For example, the “Operation ID” should follow a certain pattern (e.g., “ProjectName-Operation-###”), and if the user input violates the pattern, an error message will be displayed, and the form will not be submitted. More examples could be the weight of the sample should be a positive number, and the date of operation should be in the correct format.

File upload: There could be a some equipment configuration files or testing results users want to upload along with the form. In the later stages of the development, more advanced functions can be associated with the uploaded files, such as automatically extracting the data from the uploaded files and populate the form accordingly.

Dependencies: The form can have dynamic elements that change based on the user’s input. For example, in the case of mechanical testing, when the user selects the type of test (e.g., torsional test), the “Load frame” field will only display those equipment tha has relevant test capabilities.

Predefined calculation: Just as summing up all the elemental mass to generate the initial final mass of the alloy sample. More complex functions can be realized as well, such as calculating the density of a sample when the mass and volumes are provided by the user.

Summary

The design and usage of data collection form represent a crucial part of the data collection process in the AIMPF. The aim is to standardize the data collection process and ensure that the data is collected in a consistent manner. At this stage, users would want all the relevant and necessary data to be collected, because if missed at this stage, it would be difficult to recover the data later. This is why it is important to have conversations with domain experts to understand the requirements and design the data collection form accordingly.

Also, once the data collection form is deployed and used by the users. Extra caution would be required when modifications need to be made to the form. This is because the previously collected data will need to be modified as well to be consistent with the new form. Therefore, it is important to have a clear versioning system in place to track the changes made to the form and the data collected using the form.